Built by an engineer,

for engineers.

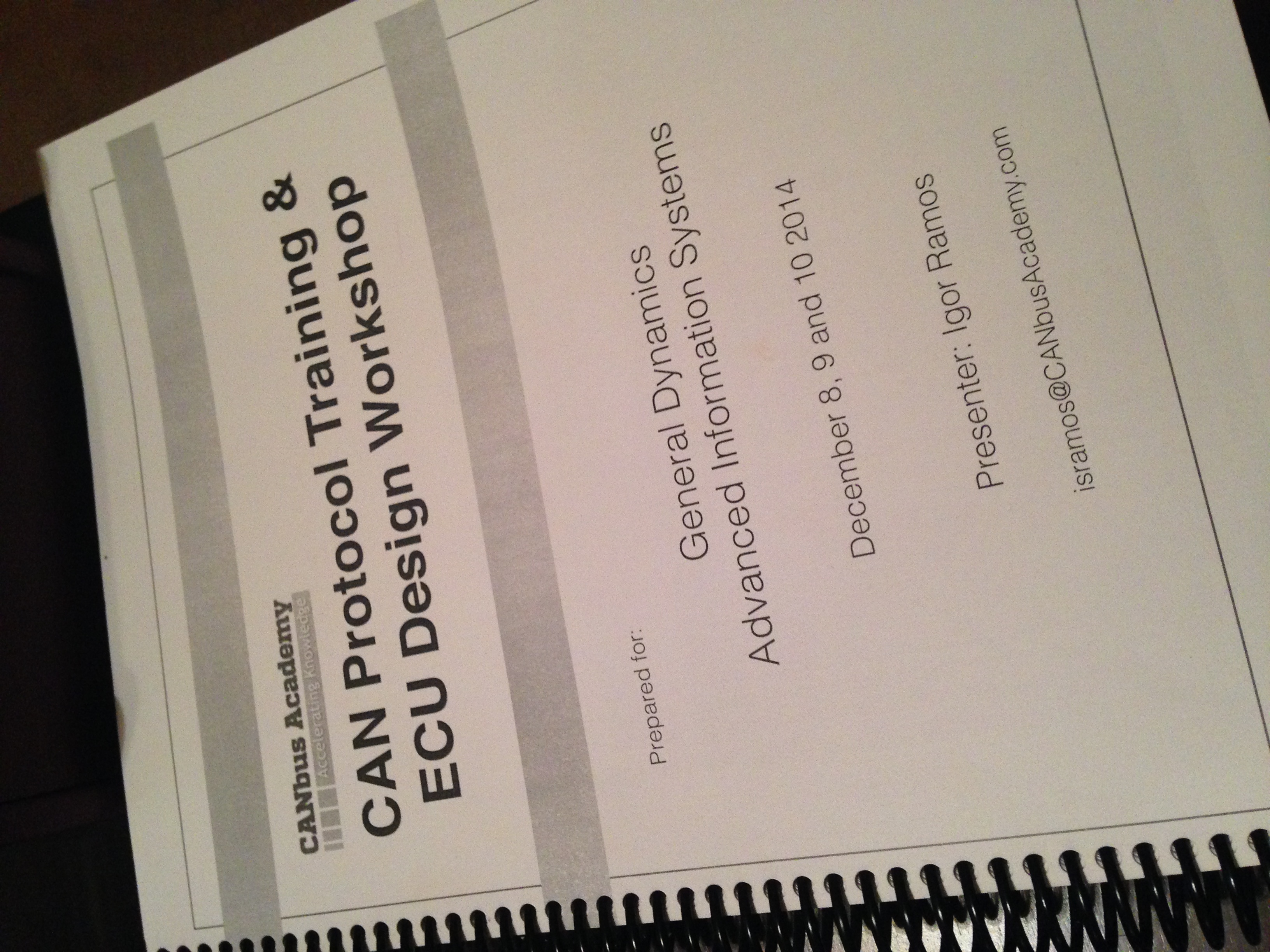

I built CANbus Academy to teach CAN bus the way I learned it — on real machines, solving real problems. I offer hands-on training, consulting, and diagnostic tools for engineers who work with vehicle networks.

My mission is straightforward: give engineers the skills to diagnose and design CAN bus systems with confidence.

About Igor Ramos

I started my career designing CAN-based electrical systems at Caterpillar, where I spent over a decade in roles ranging from R&D engineer to software architect to Technical Leader for the asphalt paver product line. That hands-on experience — designing vehicle networks, writing embedded software, and troubleshooting machines on the shop floor — is what CANbus Academy’s training is built on.

I hold 8 patents in CAN-based machine systems from my Caterpillar work, and 85+ US patents total from subsequent engineering roles at IBM and Google. My focus has always been systems that have to work in the real world.

I teach the systematic approach I wish someone had taught the technicians I worked with.

Background

CAN Bus Projects & Machine Systems

Technical Leadership

Electrical Tech Lead for Caterpillar’s Tier4f Asphalt Pavers & Screeds. Designed the machine electrical system and led the design team.

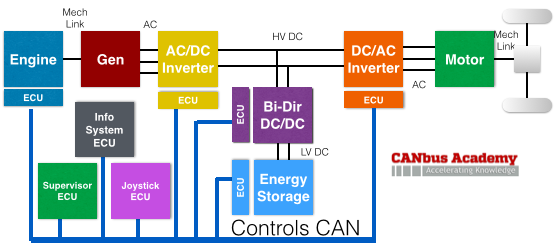

Hybrid Powertrain

Architected Battery Management System software and component integration on a prototype hybrid excavator.

Software Development

Authored production software for Caterpillar’s mining trucks and excavators.

Component Integration

Integrated CAN-based electric A/C compressor in Caterpillar D7e bulldozer.

Advanced Engineering

Rapid prototyping of leading-edge technologies years before reaching production.

Systems Engineering

Field-follow fleet of trucks with the experimental MorElectric electrical system. DOE-sponsored project.

Hands-On CAN Bus Experience

Leadership

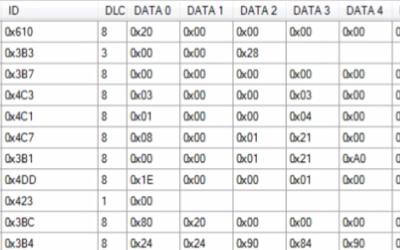

- Authored CAN specifications document for supplier

- Authored requirements for supplier to port device from 11-bit to 29-bit CAN and become SAE J1939 compliant

- Created step-by-step guide on minimum compliance to SAE J1939

Integration

- Designed and implemented vehicle network topology comprised of over 5 CAN networks and 25 CAN nodes

- Troubleshot and fixed on-highway truck with experimental high-voltage system with intermittent CAN issues

- Created busload estimation calculator to help designers size up message transmission rates

- Diagnosed CAN faults using analog signal analysis (eye diagrams) and protocol analyzers

Software

- Supported CAN bus software library written in Assembly for 8-bit microcontroller

- Wrote CCP (CAN Calibration Protocol) support for 8-bit processor and Matlab-generated embedded code

Electronics

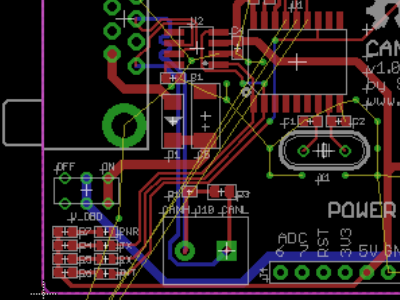

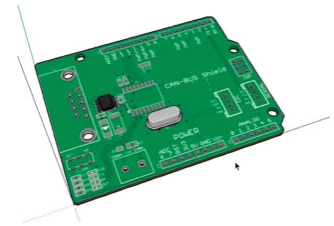

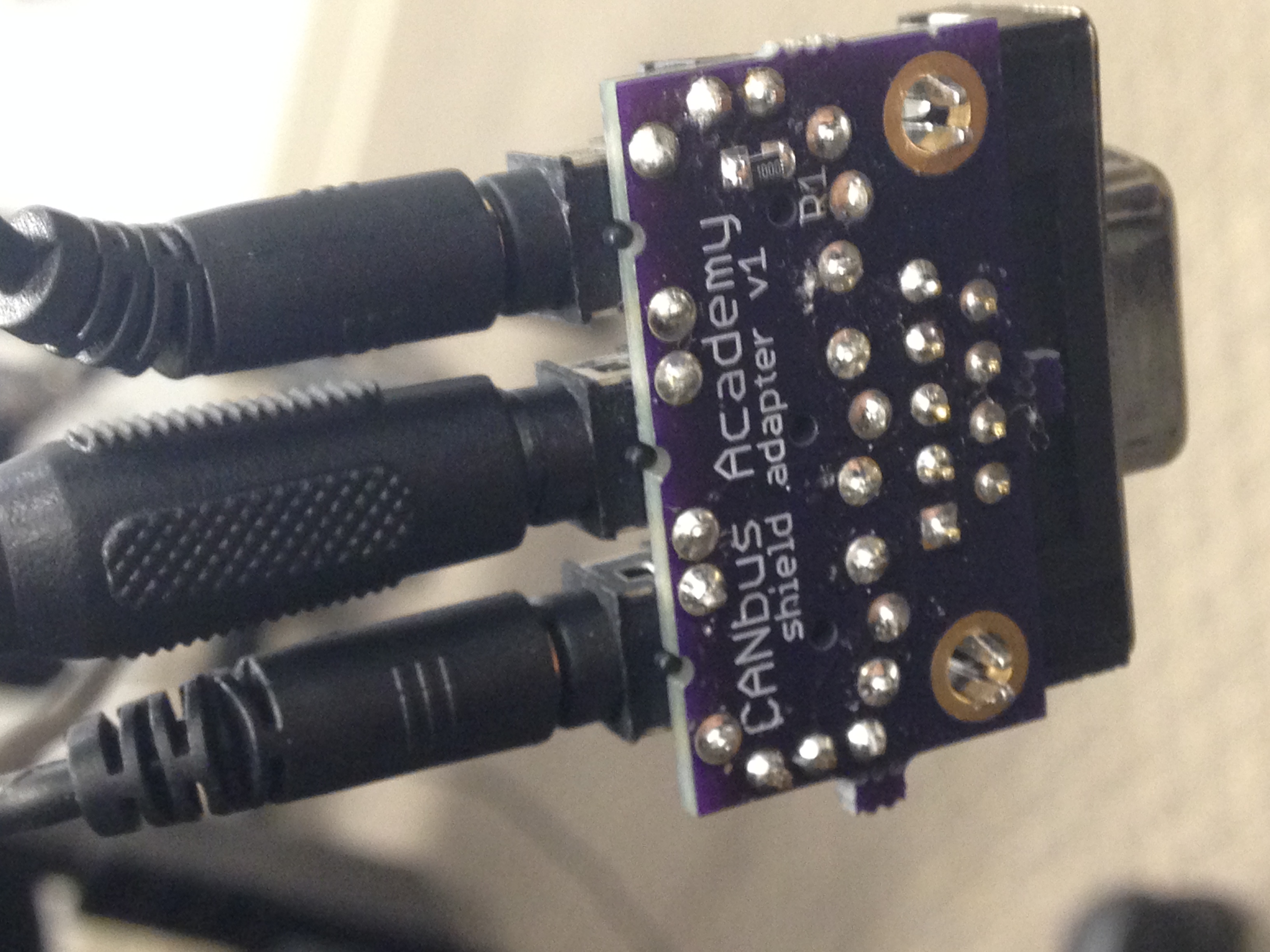

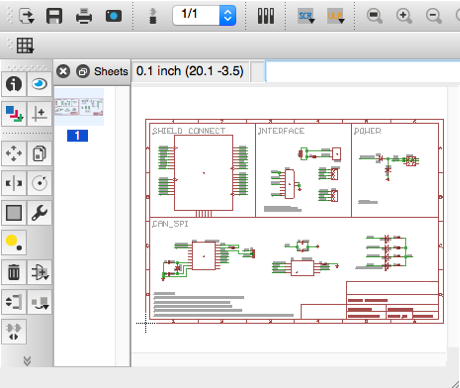

- Designed CAN-to-SPI gateway module — circuit schematic, board layout, and firmware in C

- Designed a dual CAN gateway module that off-loaded traffic from the main vehicle CAN bus

- Designed ECUs (CAN nodes) with magnetic and optical coupling

Research

- Evaluated bit error rate in CAN bus running at 1 Mbit

- Evaluated theoretical bit error rate of CAN physical layer running at 10 Mbits

Published Patents

8 patents in CAN-based machine systems shown below. 85+ total US patents across embedded systems, AI, and IoT.

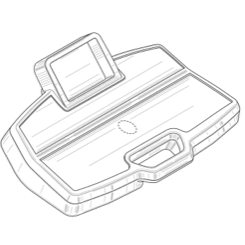

Equipment control console for Asphalt PaverCAN-based tractor operator station in production in Caterpillar’s AP10xxF family of asphalt pavers

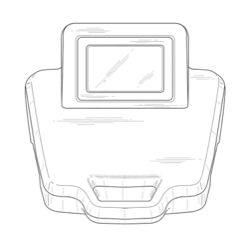

Equipment control console for Asphalt PaverCAN-based tractor operator station in production in Caterpillar’s AP10xxF family of asphalt pavers Equipment control console for ScreedsCAN-based screed operator station in production in Caterpillar’s latest generation asphalt screeds

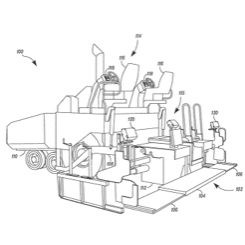

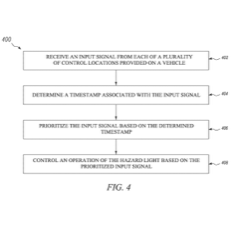

Equipment control console for ScreedsCAN-based screed operator station in production in Caterpillar’s latest generation asphalt screeds Light control systemDistributed lighting control system in latest asphalt pavers

Light control systemDistributed lighting control system in latest asphalt pavers Paving Machine with Automatically Adjusting Paver Tractor and Screed

Paving Machine with Automatically Adjusting Paver Tractor and Screed Screed extender speed control

Screed extender speed control System and method for screed extension identification

System and method for screed extension identification Systems and Methods for Detecting Ultracapacitor Cell Short Circuits

Systems and Methods for Detecting Ultracapacitor Cell Short Circuits Systems and methods for characterization of energy storage devices

Systems and methods for characterization of energy storage devices